How to Use Cord Strap for Maximum Load Security

In modern logistics and industrial packaging, ensuring the security of cargo during transportation is crucial. Proper load securing prevents damage, reduces safety risks, and improves overall efficiency. Among various strapping materials, **cord strap** stands out due to its **high strength, flexibility, and ease of use**. However, to achieve **maximum load security**, it is essential to use cord strap correctly.

This article provides a comprehensive guide on **how to use cord strap effectively**, covering selection, application techniques, and best practices for ensuring the highest level of load stability.

1. Understanding Cord Strap and Its Advantages

What is Cord Strap?

Cord strap, also known as **composite strap**, is made from high-tenacity polyester fibers bonded together. It provides a lightweight yet durable alternative to steel strapping and plastic straps.

Why Choose Cord Strap?

- **High Tensile Strength:** Despite its lightweight design, cord strap can withstand heavy loads and strong tension.

- **Shock Absorption:** The slight elasticity of cord strap allows it to absorb shocks during transport, preventing load shifts.

- **Weather Resistance:** Cord strap remains intact under extreme temperatures, humidity, and UV exposure, unlike steel straps that rust or plastic straps that become brittle.

- **Safety Features:** Unlike steel strapping, cord strap has no sharp edges, reducing the risk of worker injuries and product damage.

- **Easy Handling:** Cord strap is lightweight and requires minimal tools for application.

2. Choosing the Right Cord Strap for Your Load

To ensure **maximum load security**, selecting the right type and strength of cord strap is essential. Consider the following factors:

Load Weight and Size

- **Light to Medium Loads (Up to 500 kg / 1100 lbs):** Use standard cord straps with moderate tensile strength.

- **Heavy Loads (500 kg – 2,000 kg / 1100 lbs – 4400 lbs):** Opt for heavy-duty composite cord straps with higher tension resistance.

- **Extra-Heavy Loads (Above 2,000 kg / 4400 lbs):** Use high-strength cord straps reinforced with strong buckles.

Application Environment

- **Outdoor Shipping:** Choose UV-resistant cord straps to withstand sunlight exposure.

- **Moisture-Prone Areas:** Ensure that the cord strap is waterproof and resistant to corrosion.

- **Long-Distance Transport:** Use cord straps with high elongation properties to absorb movement without loosening.

Compatible Accessories

- **Buckles:** Metal or plastic buckles help secure the strap and allow for re-tensioning if needed.

- **Corner Protectors:** Use edge protectors to prevent strap damage when securing fragile or sharp-edged loads.

3. Step-by-Step Guide to Using Cord Strap for Maximum Load Security

Step 1: Preparing the Load

- **Stack the Cargo Properly:** Arrange the items in a stable manner to minimize movement.

- **Use Pallets or Supports:** Ensure the load is placed on a firm base for better weight distribution.

Step 2: Measuring and Cutting the Cord Strap

- **Determine the Length Needed:** Wrap the cord strap around the load and allow extra length for securing.

- **Use a Sharp Cutter:** Cut the cord strap cleanly to avoid fraying.

Step 3: Threading the Cord Strap Through a Buckle

- **Choose the Right Buckle:** Select a metal or plastic buckle that matches the strap’s strength.

- **Threading Technique:**

1. Pass the strap through one side of the buckle.

2. Loop it back and thread it through the opposite side.

3. Pull to tighten, ensuring a secure grip.

Step 4: Tensioning the Strap

- **Use a Manual or Battery-Powered Tensioner:** A tensioning tool helps apply the required force to keep the load secure.

- **Pull Firmly But Avoid Over-Tightening:** Applying excessive force may damage the cargo or the strap itself.

Step 5: Securing the Strap

- **Check for Proper Hold:** Ensure the strap is evenly tightened and the buckle is locked in place.

- **Re-Tension if Necessary:** After initial tightening, test the load by applying slight pressure to see if any adjustments are needed.

Step 6: Final Inspection and Safety Check

- **Ensure Even Pressure Distribution:** The strap should be evenly placed across the load.

- **Test for Movement:** Gently push the load to check if it remains stable.

- **Trim Excess Strap:** Cut off any excess strap length to avoid loose ends that could cause accidents.

4. Best Practices for Maximum Load Security with Cord Strap

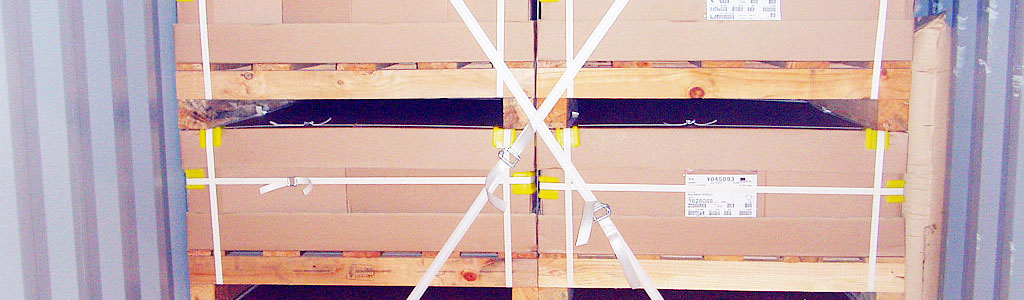

Use Multiple Straps for Extra Security

For large or heavy loads, apply at least **two or more straps** in different directions to prevent shifting.

Combine Cord Strap with Additional Securing Methods

- **Stretch Wrap or Shrink Film:** Use plastic wrapping along with cord strap for added stability.

- **Edge Protectors:** Prevent strap wear and cargo damage by using corner protectors.

Regularly Inspect and Maintain Strapping Equipment

- **Check Tensioners and Cutters:** Ensure tools are in good condition to prevent application errors.

- **Inspect Cord Straps Before Use:** Avoid using damaged or frayed straps, as they may weaken under tension.

Re-Tension During Long Journeys

For shipments with long transit times, periodically re-tighten the straps to compensate for any stretching or loosening due to vibrations.

Follow Industry Safety Standards

Adhere to load securing regulations set by **ISO (International Organization for Standardization)** or local transport safety authorities to ensure compliance.

5. Common Mistakes to Avoid

Using the Wrong Strap Type

- Avoid using **low-tensile** straps for heavy loads, as they may break under pressure.

**Improper Buckle Threading

- Incorrect threading can lead to strap slippage, compromising load security.

**Over-Tightening the Strap**

- Excessive force can damage both the strap and the cargo. Apply **firm but controlled tension**.

**Neglecting Regular Inspections**

- Always check straps for wear, fraying, or weakening before use.

6. Conclusion

Using **cord strap** correctly is essential for **maximum load security** in transportation and storage. By selecting the right strap type, applying proper tensioning techniques, and following best practices, businesses can ensure that their cargo remains **stable, protected, and safe** throughout the supply chain.

Cord strap offers a **cost-effective, durable, and user-friendly** solution for securing loads across various industries, from logistics and shipping to manufacturing and agriculture.

By following the steps outlined in this guide, you can maximize the effectiveness of **cord strap**, reduce risks, and enhance overall transportation efficiency. Whether securing heavy machinery, fragile goods, or bulk cargo, **cord strap ensures peace of mind and superior load stability**.