How Composite Strapping Enhances Safety and Efficiency in Logistics

In the logistics industry, ensuring the safety of products during transportation and improving operational efficiency are paramount. To achieve these objectives, companies constantly seek better packaging solutions. Among these, composite strapping has emerged as one of the most effective and reliable materials for securing goods. Known for its strength, flexibility, and cost-effectiveness, composite strapping offers numerous advantages in enhancing safety and efficiency in logistics operations. This article explores how composite strapping contributes to safer, more efficient logistics practices, benefiting both businesses and consumers.

What is Composite Strapping?

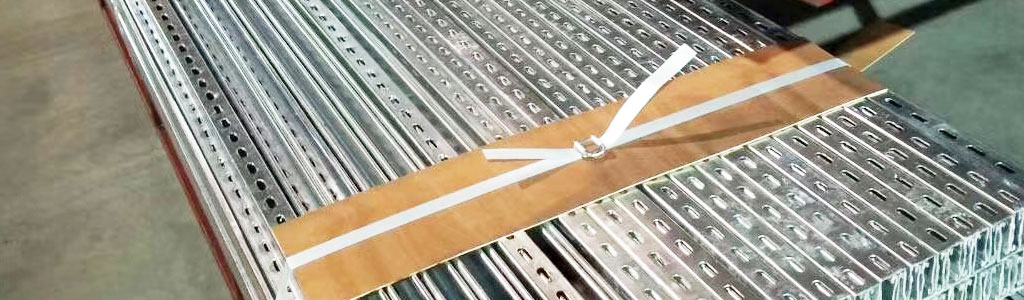

Composite strapping is an industrial packaging material made from a blend of high-strength synthetic fibers, typically polyester or polypropylene, coated with a plastic layer. This fusion of materials results in a highly durable yet flexible product that can withstand the rigors of transport while being lightweight and easy to handle. Unlike metal strapping, composite strapping is resistant to corrosion, easier to apply, and less hazardous for workers to handle. Its ability to secure a wide variety of items—ranging from heavy machinery to small packages—makes it a versatile solution in logistics.

Enhancing Safety in Logistics with Composite Strapping

One of the most critical concerns in logistics is the safe transport of goods. Whether products are being shipped via land, sea, or air, ensuring their security during transit is vital. Composite strapping plays a significant role in enhancing safety across several key areas:

1. **Preventing Product Damage**

One of the primary functions of strapping is to keep products securely in place and prevent shifting during transportation. When goods move around inside containers or trucks, they are at risk of being damaged due to friction, impacts, or compression. Composite strapping holds items tightly together, reducing the chance of movement and minimizing the risk of damage. For example, when transporting fragile items or valuable machinery, composite strapping ensures that each package remains stable and protected.

Additionally, composite strapping’s resistance to abrasion means it will not cause damage to the product itself. Unlike metal straps, which may scratch or dent goods, composite strapping offers a smooth surface that holds items without damaging them. This is especially beneficial when transporting sensitive materials, such as electronics, glass, or metal parts, where even minor damage could render them unusable.

2. **Reducing Risk of Injury**

In traditional logistics operations, metal strapping has long been the norm. However, metal strapping is rigid and sharp, posing a safety hazard to workers. These straps can cause cuts or other injuries if not handled with care. Composite strapping, on the other hand, is designed to be safer for workers. It’s smoother to the touch, eliminating sharp edges that could result in accidental injuries.

Additionally, composite strapping is easier to handle and apply compared to metal strapping. Workers can manually tension composite strapping with minimal effort, reducing strain and the risk of physical injury associated with more cumbersome materials. With less reliance on specialized tools and fewer manual handling risks, composite strapping contributes to a safer working environment.

3. **Eliminating Corrosion Risks**

Corrosion and rust are common issues when using metal strapping, especially in humid or outdoor environments. This not only weakens the strapping itself but can also cause it to fail during transit, leading to potential safety hazards. Composite strapping, however, is resistant to water, chemicals, and UV exposure. It does not corrode, rust, or degrade over time, which ensures that the straps remain strong and reliable throughout the transport process, even in adverse weather conditions. This enhanced durability reduces the likelihood of accidents related to weakened or compromised strapping.

Improving Efficiency in Logistics with Composite Strapping

In addition to its safety benefits, composite strapping also plays a vital role in improving efficiency in logistics operations. By reducing labor costs, speeding up packaging processes, and offering a more cost-effective solution, composite strapping enhances the overall efficiency of logistics management.

1. **Faster and Easier Application**

One of the most significant advantages of composite strapping is its ease of use. Unlike metal strapping, which often requires special tools and equipment, composite strapping is lightweight and can be applied using simple, handheld tensioning devices. This ease of use speeds up the packaging process and reduces the amount of time required for securing shipments.

Furthermore, composite strapping is highly flexible, allowing it to be applied to a variety of package shapes and sizes. Whether a manufacturer is shipping a small box or a large pallet, composite strapping can adapt to fit different load configurations. This versatility eliminates the need for specialized straps or complicated packaging processes, making it a time-efficient solution for diverse logistics needs.

2. **Reducing Material Costs**

Cost-efficiency is a critical consideration in logistics, where companies constantly seek to reduce expenses while maintaining quality. Composite strapping is a more affordable alternative to metal strapping, which is heavier and often more expensive to manufacture and transport. Composite strapping’s lightweight design also reduces shipping costs, as it adds minimal weight to the overall load.

Moreover, the durability of composite strapping ensures that it can be reused multiple times, providing further cost savings for businesses. Since composite strapping resists wear and tear better than traditional materials, companies can use it for several shipments before needing to replace it, leading to lower long-term expenses.

3. **Increased Load Security and Stability**

The ability of composite strapping to securely hold goods in place leads to a more stable and efficient load configuration. When items are properly secured with composite strapping, the entire shipment is less likely to shift or become unstable during transit. This not only reduces the chance of accidents but also minimizes the risk of delays caused by damaged or misaligned shipments.

With composite strapping ensuring that goods remain in their optimal positions, logistics providers can maximize the use of available space in transportation containers, leading to better space optimization and reduced shipping costs. The result is an overall more efficient logistics operation that benefits both shippers and receivers.

4. **Sustainability Benefits**

As businesses and consumers increasingly prioritize sustainability, composite strapping provides a more eco-friendly alternative to traditional packaging materials. Many composite strapping products are made from recyclable materials, helping companies reduce waste and minimize their environmental impact. Furthermore, composite strapping’s long-lasting durability means fewer replacements are necessary, reducing the amount of strapping material needed and contributing to a more sustainable supply chain.

Conclusion

Composite strapping has proven to be an invaluable tool in enhancing both safety and efficiency in logistics. Its superior strength, resistance to environmental factors, and ease of use make it an ideal solution for securing products during transport. By preventing damage, reducing injury risks, and increasing packaging speed, composite strapping enhances safety across the entire logistics process. On the efficiency side, it helps companies lower material and shipping costs, while ensuring more stable, optimized loads.

As logistics operations continue to evolve, composite strapping offers a cost-effective, sustainable, and safer alternative to traditional packaging materials. Whether in warehousing, shipping, or freight management, its versatility and performance make composite strapping an essential element of modern logistics practices.