Baler Press Strap Maintenance Tips to Ensure Longevity and Efficiency

In the waste recycling industry, baling presses play a pivotal role in compressing recyclable materials into compact, manageable bundles for transportation and storage. One essential component of the baling process is the baler press strap, a powerful tool that ensures the integrity of compressed bales. Baler straps are used to bind materials such as cardboard, paper, plastic, and metals, ensuring that they remain secure during handling and shipping. However, to maintain the efficiency of your baling operations and ensure the longevity of your baler press straps, proper maintenance is crucial. In this article, we will discuss key tips for maintaining baler press straps, which will help maximize performance and prolong the lifespan of both the straps and the baling equipment.

1. **Understand the Role of Baler Press Straps in Waste Recycling**

Before diving into maintenance tips, it’s important to understand the role baler press straps play in the waste recycling process. Baler straps are used to tightly bind recycled materials into dense, secure bales. These bales make it easier to transport and store large volumes of waste materials while preventing spills and reducing the risk of contamination.

Baling presses are employed across various recycling sectors, including paper and cardboard, plastics, metals, textiles, and e-waste. Whether it’s cardboard boxes, plastic bottles, or metal scrap, the strapping ensures that the bales stay intact during the collection, transportation, and storage phases.

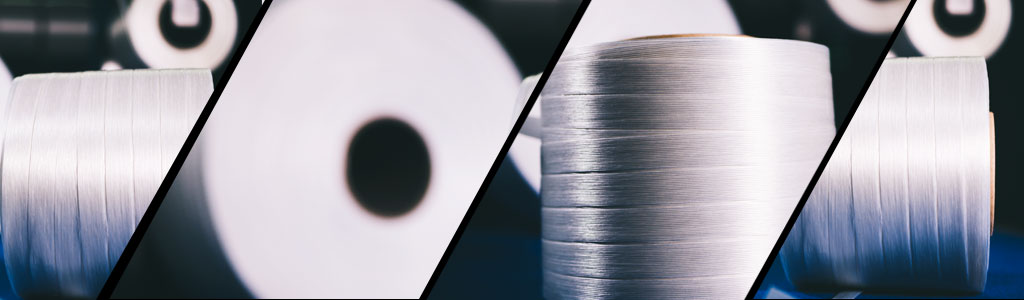

In a recycling facility, the type of materials being processed can vary in size, shape, and density. As a result, different types of baler press straps—such as polyester (PET), polypropylene (PP), and steel—are used based on the specific needs of the materials being compacted.

2. **Regularly Check and Replace Baler Press Straps**

Baler press straps undergo significant stress during operation, particularly when dealing with heavy, dense materials. Over time, the straps can become worn out, damaged, or lose their elasticity. Therefore, regular inspection is essential to ensure the straps are functioning optimally.

**Maintenance Tip 1:**

Inspect baler straps before each shift to identify any signs of wear or damage. Look for frayed edges, cuts, or signs of stretching. It’s important to replace any straps that show signs of damage or wear to prevent failure during operation.

**Maintenance Tip 2:**

Check the tension of the straps before each cycle. Over-tightening or under-tightening the strap can lead to premature wear or insufficient load security. Properly tensioned straps ensure that the bales stay intact during transit while preventing excessive strain on the press.

Regular maintenance of the straps will help avoid unexpected downtimes, material spillage, and potential safety hazards.

3. **Keep the Baler Press Clean**

A clean baler press ensures smooth operation and reduces the risk of malfunction. When strapping materials are being processed, dirt, dust, and debris can accumulate on the press, which can affect the quality of the straps and cause operational inefficiencies.

**Maintenance Tip 3:**

Clean the baler press regularly to prevent the build-up of debris. Check areas where the strap feeds into the machine and where it exits to ensure there are no obstructions that could interfere with the strapping process. Cleaning the strapping mechanism also prevents dirt from being transferred onto the baler straps, which can lead to damage or weakening of the material.

A clean baler press reduces friction, ensures a smoother operation, and extends the lifespan of both the baling machine and the straps.

4. **Ensure Proper Storage of Baler Straps**

Proper storage of baler press straps is often overlooked but is vital to maintaining the quality and durability of the straps. Exposure to environmental factors such as moisture, extreme temperatures, and sunlight can deteriorate the material, weakening its strength and elasticity.

**Maintenance Tip 4:**

Store your baler press straps in a dry, cool environment away from direct sunlight. This will help preserve their strength and prevent them from becoming brittle. Avoid storing straps in areas where they are exposed to excessive heat, humidity, or chemicals, as these conditions can cause the straps to degrade quickly.

By taking care to store the straps correctly, you can prolong their usability and ensure they maintain their integrity during baling operations.

5. **Use the Right Type of Baler Strap for Specific Materials**

Not all materials in the waste recycling process are the same, and neither are the requirements for baler straps. The type of strap used can make a significant difference in both the performance of the baler and the efficiency of the recycling process.

**Maintenance Tip 5:**

Choose the appropriate type of baler press strap based on the materials being processed. For example, polyester straps are commonly used for lightweight materials like cardboard and plastics, while steel straps are often preferred for heavier materials like metals and dense waste. Using the wrong type of strap for the material being processed can lead to premature wear, inefficient strapping, and poor bale integrity.

Using the right material ensures the straps work efficiently, reducing wear and tear on the press while ensuring strong, secure bales.

6. **Monitor the Tension and Alignment of the Strapping Mechanism**

Incorrect tension or alignment of the baler press straps can lead to operational inefficiencies and premature wear. When the strapping mechanism is misaligned or over-tightened, it can cause unnecessary stress on both the baler press and the straps.

**Maintenance Tip 6:**

Regularly check the alignment of the strapping mechanism and ensure that the tension is appropriately set for the material being processed. If the strap is too tight, it can break or wear out quickly. If it is too loose, it won’t adequately secure the bales. Properly tensioned and aligned straps will reduce strain on the baler press, increase the lifespan of the straps, and enhance overall efficiency.

Routine monitoring of the strapping mechanism helps maintain the smooth operation of your baler press and reduces downtime caused by equipment malfunctions.

7. **Lubricate and Maintain the Baler Press Components**

Lubrication of moving parts in the baler press is vital for smooth and efficient operation. Proper lubrication reduces friction, wear, and heat build-up, which can extend the lifespan of the machine and the straps.

**Maintenance Tip 7:**

Lubricate all moving parts of the baler press according to the manufacturer's recommendations. Ensure that rollers, guides, and other components that interact with the strapping are well-maintained to minimize friction and wear on the straps. Keeping these components well-lubricated ensures that the baler press operates at peak efficiency, reduces stress on the straps, and helps prevent damage.

8. **Train Staff on Proper Baler Press Strap Handling**

Employee training is a key element of maintaining the effectiveness of your baler press straps. Proper handling, installation, and operation of the baling press can reduce the risk of equipment failure, strap damage, and inefficient processing.

**Maintenance Tip 8:**

Ensure that staff are trained to handle the baler press straps correctly. This includes loading the straps properly into the machine, checking for alignment, and ensuring that tension settings are adjusted for the material being processed. Proper training can prevent common mistakes that lead to unnecessary wear on both the baler press and the straps.

Conclusion

Baler press straps are integral to the efficiency and safety of the waste recycling process. By properly maintaining and caring for your baler straps, you can ensure that your recycling operations run smoothly, reduce downtime, and increase the overall lifespan of your equipment. Regular inspection, correct storage, using the right material, and keeping the baler press clean and well-lubricated are all essential steps in maintaining the efficiency of your baling operations.

By following these maintenance tips, you can optimize the performance of your baler press, improve the quality of your bales, and contribute to a more efficient and sustainable waste recycling process. Whether you are processing cardboard, plastic, or metals, taking care of your baler press straps will lead to improved productivity and reduced costs in the long run.